|

Op Panel Upgrade for 9585 K/N

IBM TDB - Information Panel (block diagram of the 95 XP Op Panel)

General Description

95 XP Op Panel Schematic

95 XP Op Panel Connector Pinout

95A Op Panel Schematic

95A Op Panel Connector Pinout

85 Indicator Panel Schematic

85 Indicator Panel Connector Pinout

3511 Indicator Panel Schematic

3511 Indicator Panel Connector Pinout

Power Switch

LED Display Module

Display Module Socket

Op Panel Speaker

Serial Data Link (95A Op Panel Only)

Multimedia Link (95A Op Panel Only)

Op Panel Presence Detect

95 XP Op Panel - Hidden Remote IPL Switch (SW1)

Supposed Origin of Op Panel Board

Cheap Op Panel Lens Redo

Thoughts on Adding a HD LED

Peter's Two-Color LED (Works on early non-shuttered switch only)

Shorney's Shortcut

Button Sizes

Early 95s without Shutter over Power Switch

Free PS/2 Model 95 Power Switch Upgrade

Op Panel Bezels and PCBs

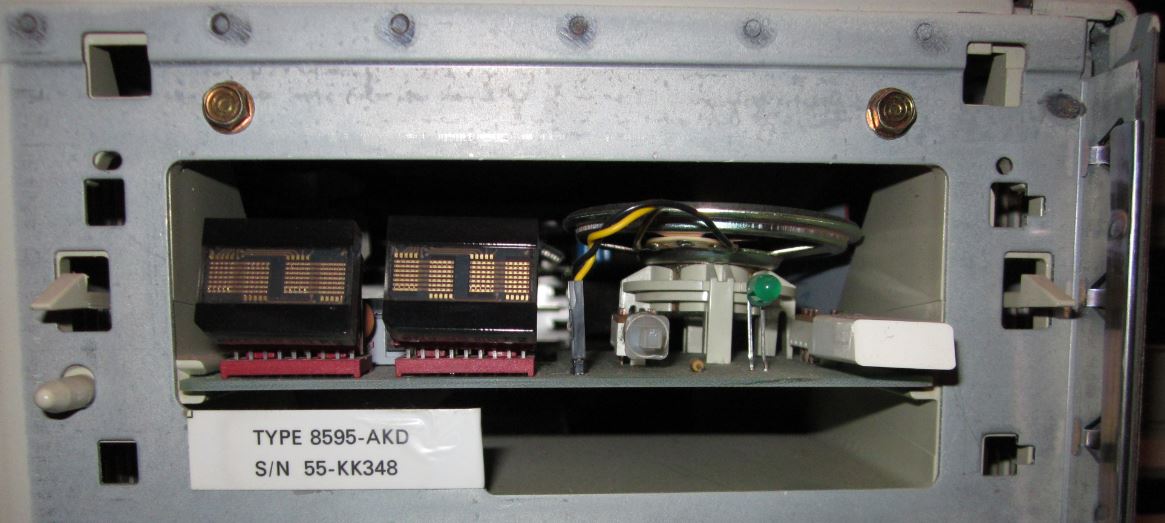

8595 Op Panel

3511 Op Panel

9585 Op Panel

9595A Op Panel

Power Switch Test / Jump Start

Register Information

LED Panel Driver Programs

Odd LED Behavior

8 "Lights" on Op Panel

General Description

Planar provides a 34-pin (2x17) Berg connector to the operator panel. A

matching connector can be found on the panel itself. The panel consists of:

Model 95 XP

Model 95A

Model 85

3511 Enclosure

The original Model 85 "X" planar supports

the 95(A) Op Panel with the LED display out-of-the-box,

no modifications

are required.

The newer 85 "K/N" planar still has a

provision for the Op Panel support logic, however the circuitry is not

populated - see HERE for info on how to

re-enable this feature.

95 XP Op Panel Schematic

ASSY FRU P/N 92F1319, PCB FRU P/N 33F8434, PCB P/N 33F5412

No active components aside from the two LED display units and the Power Good LED.

SW1 enables/disables the "Remote Power-ON" feature.

95 XP Op Panel Connector Pinout

| Pin | Description |

Pin | Description |

| 1 | -Power-ON Request |

2 | -Power Good |

| 3 | Data 0 |

4 | Hardfile LED* |

| 5 | Data 1 |

6 | -Unattended (?) * |

| 7 | Data 2 |

8 | Ground |

| 9 | Data 3 |

10 | Ground |

| 11 | Data 4 |

12 | Ground |

| 13 | Data 5 |

14 | Ground |

| 15 | Data 6 |

16 | Ground |

| 17 | Address 0 |

18 | Ground |

| 19 | Address 1 |

20 | Ground |

| 21 | -Write LED (high) |

22 | Ground |

| 23 | -Write LED (low) |

24 | Ground |

| 25 | +5 V |

26 | Ground |

| 27 | +5 V |

28 | Ground |

| 29 | -Remote Power-ON Request |

30 | -Read LED (all) (?)** |

| 31 | +5 V |

32 | Ground |

| 33 | Speaker Data |

34 | Ground |

(?) - needs confirmation

* - signal not used by the 95 XP Op Panel Board

** - signal grounded on the 95 XP Op Panel Board

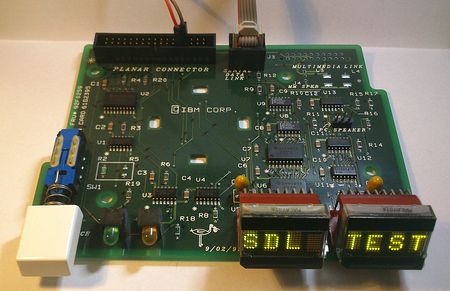

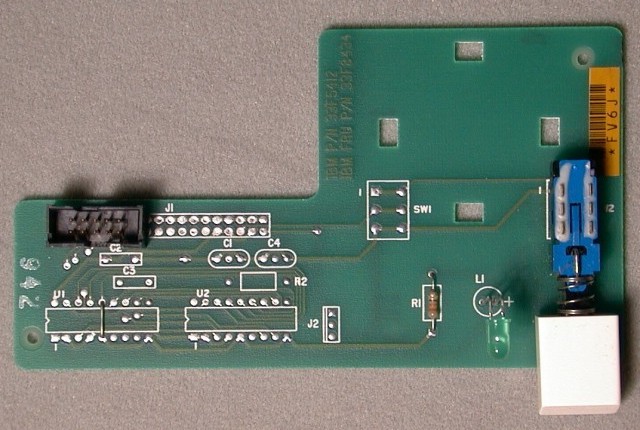

95A Op Panel Schematic

ASSY FRU P/N 61G2393, PCB FRU P/N 92F0259, PCB RAW CARD P/N 61G2395

Active components: two LED display units, Power Good LED, Hard File LED, and

a bunch of 74xx logic ICs. Together the ICs make up a decoder for the

"Serial Data Link" interface.

There is also a provision for something called "Multimedia Link".

R2 is a zero-ohm SMD resistor "jumper". R3 would be another one, but it's

not populated. These jumpers change behavior of the "-Remote Power-ON Request"

signal (J1 pin 29) in regard to the power switch (SW1).

95A Op Panel Connector Pinout

(source)

| Pin | Description |

Pin | Description |

| 1 | -Power-ON Request |

2 | -Power Good |

| 3 | Data 0 |

4 | Hardfile LED |

| 5 | Data 1 |

6 | -Unattended |

| 7 | Data 2 |

8 | Presence Detect 3 |

| 9 | Data 3 |

10 | Presence Detect 2 |

| 11 | Data 4 |

12 | Presence Detect 1 |

| 13 | Data 5 |

14 | Presence Detect 0 |

| 15 | Data 6 |

16 | Ground |

| 17 | Address 0 |

18 | Ground |

| 19 | Address 1 |

20 | Ground |

| 21 | -Write LED (high) |

22 | Ground |

| 23 | -Write LED (low) |

24 | Ground |

| 25 | +5 V (Op Panel) |

26 | Data 7 |

| 27 | +5 V (MM Link) |

28 | Ground |

| 29 | -Remote Power-ON Request |

30 | -Read LED (all) |

| 31 | +5 V (MM Link) |

32 | Speaker Ground |

| 33 | Speaker Data |

34 | Speaker Ground (N/C) |

85 Indicator Panel Schematic

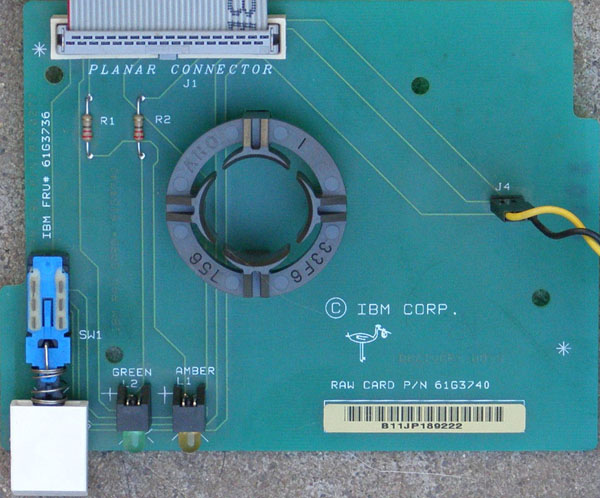

ASSY FRU P/N 61G3739, PCB FRU P/N 61G3736, PCB RAW CARD P/N 61G3740

Very simple board. No active components aside from the the Power Good LED

and Hard File LED.

It uses the same connector and pinout as the much fancier Op Panel in Model

95, but most of the pins are unused here.

85 Indicator Panel Connector Pinout

(source)

| Pin | Description |

Pin | Description |

| 1 | -Power-ON Request |

2 | -Power Good |

| 3 | Reserved |

4 | Hardfile LED |

| 5 | Reserved |

6 | -Unattended |

| 7 | Reserved |

8 | Reserved |

| 9 | Reserved |

10 | Reserved |

| 11 | Reserved |

12 | Reserved |

| 13 | Reserved |

14 | Reserved |

| 15 | Reserved |

16 | Ground |

| 17 | Reserved |

18 | Ground |

| 19 | Reserved |

20 | Ground |

| 21 | Reserved |

22 | Ground |

| 23 | Reserved |

24 | Ground |

| 25 | +5 V |

26 | Reserved |

| 27 | +5 V |

28 | Ground |

| 29 | -Remote Power-ON Request* |

30 | Reserved |

| 31 | +5 V |

32 | Speaker Ground |

| 33 | Speaker Data |

34 | Speaker Ground |

* - signal listed as reserved in the Model 85 Technical Reference

Most of the "Reserved" lines are actually connected and wired to support the

9595 Op Panel. Some logic is missing from the planar, but it's possible to

bring the feature back. More info HERE.

3511 Indicator Panel Schematic

ASSY FRU P/N 64F0143, PCB FRU P/N 33F8434, PCB P/N 33F5412

The same PCB as the 95 XP with only the power switch, Power Good LED &

resistor, and a smaller (10-pin) header are populated.

3511 Indicator Panel Connector Pinout

| Pin | Description |

Pin | Description |

| 1 | -Power-ON Request |

2 | -Power Good |

| 3 | N/C |

4 | -Power-ON Request * |

| 5 | N/C |

6 | N/C |

| 7 | Ground * |

8 | Ground |

| 9 | +5 V |

10 | N/C |

* - signal not used by the 3511 Op Panel Board

Power Switch

The switches used on the Op Panel are of the DPDT

(Double-Pole Double-Throw) push-button type (i.e. GC 35-491 or compatible -

diagram,

datasheet).

You can also unsolder the other switch (SW1) on op panels with two switches

and use it as a replacement. It's the same type of switch. Doing so will cost

you the Remote IPL feature.

See how to test the switch / jump start your machine

HERE.

LED Display Module

It's HDLG-2416LED from the HDLX-2416 Series.

Smart Alphanumeric Display Built-in RAM, ASCII Decoder, and LED Drive

Circuitry Software Controlled Dimming Levels and Blank 128 ASCII Character

Set.

Each module can display 4 characters with 5-by-7 dot pattern.

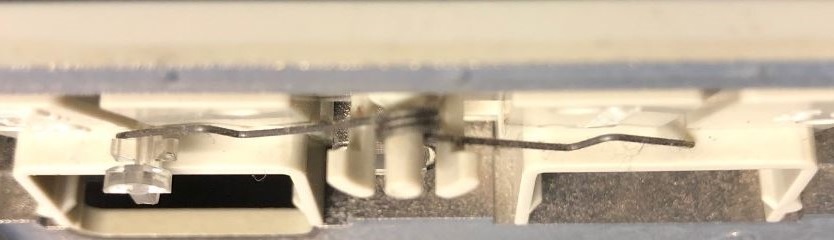

Display Module Socket

The angled DIP-18 socket was manufactured by

Aries Electronics - you can see their

logo inside the socket cavity (underneath the LED module).

Possibly a customized version of Series 800 Vertisocket to achieve the

desired angle?

Series 800 Vertisocket Datasheet (new)

Series 800 Vertisocket Datasheet (old)

"Consult factory for other display angles"

Op Panel Speaker

95 XP and 95A use the same type of internal speaker: 8 ohms, 0.3 W, 66 mm

outer diameter.

The speaker is marked as: AAP, 66R, 8ohm, 0.3W, PROC

Speaker connector pinout:

| Pin | Description |

| 1 | Speaker Signal (Data) |

| 2 | —* |

| 3 | Speaker Ground |

* - Model 85 Op Panel has another Speaker Ground on pin 2, but this is not

used by the speaker itself.

The speaker is driven by a simple amplifier that is located directly on the

planar board. More info can be found

HERE

(Describes Model 95A, but audio stage in Models 95 XP and 85 is similar).

Serial Data Link (95A Op Panel Only)

Serial Data Link aka Serial Diagnostic Link or SDL is a direct communication

channel between the Processor Complex (Type 4 only) and the Op Panel. It's

explained in greater detail HERE.

Serial Data Link Connector (J2) Pinout:

| Pin | Description |

Pin | Description |

| 1 | Display Sense |

2 | Display Strobe |

| 3 | Display Reset |

4 | — |

| 5 | — |

6 | — |

The SDL port is used by the POST routine to output early diagnostic

information. Go HERE

for more info.

The link is mapped to port E1h. If you want to learn how to use it, visit

THIS page.

The primary benefit of the SDL port is that it can be used to output info to

the Op Panel before the system channel is initialized, and even if the planar

isn't fully operational. Aside from the +5 V power rail, no other connections

between the planar and Op Panel are required for the serial link to operate.

As can be seen here:

The two wires connected to the planar connector supply the panel with power,

pin 25: +5 V (red wire), and pin 28: ground (black wire). The system was

jump-started by shorting pin 1: "-Power-ON Request" to pin 24: ground (this was

done directly on the planar).

Multimedia Link

(95A Op Panel Only)

The 95A Op Panel has a provision for something called "Multimedia Link" but

the related components are not populated. I'm not sure what exactly was this

intended for, but likely for some kind of Ultimedia-like option. Possibly a

separate board that would fit upside-down into the second "rail" set, right

under the main Op Panel PCB. The second board would probably provide a pair of

front panel audio connectors, a volume pot (judging by the matching cutout in

the DASD cage structure), and perhaps an audio amp as well.

Multimedia Link Connector (J3, unpopulated) Pinout:

| Pin | Description |

Pin | Description |

| 1 | Presence Detect 2 |

2 | — |

| 3 | Presence Detect 1 |

4 | — |

| 5 | — |

6 | — |

| 7 | PC Speaker Ground |

8 | — |

| 9 | PC Speaker Data |

10 | +5 V |

| 11 | — |

12 | MM Speaker Ground |

| 13 | MM Speaker Signal |

14 | MM Speaker Ground |

| 15 | — |

16 | +5 V |

| 17 | — |

18 | +5 V |

| 19 | — |

20 | +5 V |

Op Panel Presence Detect (by Tomas Slavotinek)

Before I forget (again...), here is some more info about the Op Panel

presence detect logic of the 9595 2S2P planar.

It's actually even more primitive than I originally thought. There are no

pullups and inverters on the planar. The pins are simply "floating low" (logic

0), and pullup(s) on the Op Panel and Multimedia Panel are used to force the

bits high (logic 1).

This unfortunately means that the 9595 2S2P planar can't differentiate

between the older 9595 Op Panel (the one w/o HD LED) and the 9585 Indicator

Panel. (Pins that are floating low, won't change their state when left floating

or when grounded.)

It can only detect the newer 9595 Op Panel and the unreleased Multimedia

board that would connect to the unpopulated Multimedia Link connector.

The Presence Detect bits 0, 1, and 3 are occupying pins 14, 12, 10, and 8 in

that order. As can be seen HERE.

The four PD bits can be obtained via the Planar POS register cluster in 4

simple steps:

- enable Group 1 Planar registers (set bit 7 of port 94h to 0)

- select the Operator panel information ("Index 7" = 1Dh to port 103h)

- read the Operator panel present info (low 4 bits)

- disable Group 1 Planar regs (set bit 7 of port 94h back to 1)

The mapping is straightforward:

- PD 0 (pin 14) is mapped to the least sig. bit - bit 0 of reg 103h

- PD 1 (pin 12) to 103h bit 1

- PD 2 (pin 10) to 103h bit 2

- PD 3 (pin 8) to 103h bit 3

There are no inverters, so unconnected or grounded pins will show as 0. Pins

tied to +5 V via pullups will show as 1.

Base Op Panel Presence Detect Codes

"0000" - the older 8595 Op Panel

"0000" - the 9585 Indicator Panel

"1000" - the newer 9595 Op Panel (pin 8 tied to 5 V on the panel board)

Multimedia Panel Presence Detect Codes

The newer 95A Op Panel with the Multimedia board will come up as "1xy0"

where "x" depends on the state of the Multimedia Link pin 1, and "y" on the

state of the Multimedia Link pin 3. This gives us 3 other possible values:

"1100" - 95A Op Panel with MML pin 1 tied to 5 V

"1010" - 95A Op Panel with MML pin 3 tied to 5 V

"1110" - 95A Op Panel with MML pins 1 and 3 tied to 5 V

The T4 SurePath BIOS only uses this when Int 15 function CBh ("LED display

- print character at position") is called. It will return 86h - "Not supported"

if the function is called on a 2S2P 9595 that doesn't have the newer Op Panel

connected to it. The older 1S1P planar doesn't have the Presence Detect logic

at all, so the BIOS assumes that the panel is connected and blindly outputs the

data to ports 108 - 10Fh.

The POST routine doesn't actually check the Presence Detect bits it

seems.

Note: One could use the MML pins 1 and 3 as a

cheap GPIO ports... You would have to poll it, and it's just GPI without the O

part.

Debugging comes to mind as one potential use. It may be useful for our BIOS

experiments - to switch between two different code paths or whatever.

Devkits/devboards often have a set of GPIO ports (sometimes hardwired to

switches and LEDs) for this very purpose.

95 XP Op Panel - Hidden Remote IPL Switch (SW1)

What's the switch SW1 for on the op panel PCB?

Tom says:

The SW1 switch is normally hidden behind the Op Panel Bezel.

Contrary to what has been said about it not having any

function in the Model 95, based on its wiring and some testing I have

determined that it enables/disables the "Remote Power-ON" feature.

This allows the system unit to be turned on and off from an

external source - via the J4

pin header on the planar board. For this to work the hidden SW1 switch must

be pressed down, and then it's possible to power the system on by grounding pin

2 of J4, and power it off again by removing this connection. The system will

power down only if the main power switch (SW2) remained in the OFF

position.

The J4 connection would be realized using an externally powered

electronic switch - relay, semiconductor etc. The control signal could be then

supplied from a device connected to a telephone line or some other source.

Ed. Now we know its real name -

Remote Initial Program Load (IPL) Switch (source).

Supposed Origin of Op Panel Board

From Peter:

Back in 1991 (or around) when there were technical trainings on

the 8595s held at IBM someone asked the very same question:"What's the second,

hidden switch for?"

The IBM instructor told us, that the panel card has been taken from some

3270 control unit and the second switch was used to set the IPL mode of that

box or to clear audible alarms or such. "It is not used with the PS/2 -

therefore it is hidden behind the bezel." If it *were* used we have had two

switches in the front.

I used to use the second switch a) as a replacement for the power switch,

which tends to wear out after some time or b) modified the card and bezel to

have the switches in parallel, so that you cannot accidentally power down the

server. One needed to pry in a tiny hole to operate the second switch too to

get it shut down...

Tom reacts:

I know, I know, who am I to question Peter's story, but eh, here

we go... First of all, physical design of the board matches the Model 95 system

unit - it fits perfectly to the 5.25" bay, and the LED display sockets are

angled to match the PS/2-styled bezel. Could that be just a coincidence? I

would say no, unless the "Control Unit" it was supposedly designed for, was of

the PS/2 design as well (or perhaps even based on the Model 95 unit). But in

that case why would they populate the extra switch if it was unused? Or were

the panels already assembled and they just had some spare? I find all this

rather strange...

Based on these observations and my experience, I would say that it was

designed specifically for the Model 95 line, and the switch was either intended

to be hidden - for "operator's eyes and hands only" (you have to unlock and

remove the front bezel to access it, but you don't have to poke inside the

machine itself to do so), and/or it was exposed only on some special bid 95s...

After all the *later* 8595 bezel has a

sub-assembly with a provision for the second switch! It would make no sense to

design and add that part for the revised bezel, if the switch served no

purpose, you would just stop populating it...

Ed. Some IBM patents show the DASD cage with an

early 8595 dual-button Op Panel bezel installed

(i.e. EP0426330B1),

supporting the above explanation:

Ed. Tom: As I have discovered the switch

actually *does* serve a purpose in the Model 95 - it

enables the "Remote Power-ON" feature.

Cheap Op Panel Lens Redo

From Tony Ingenoso:

Tired of the scuffed up scratched LED display panel on

your M95? Would you like it to look as if it were new again?

Here's how -- it takes about 1 minute and makes all the difference in the

world from an aesthetic point of view.

- Remove the bezel containing the LED panel cover.

- Pop the scratched up plastic cover off.

- Look at the locking tabs on the sides - one is a tad wider than the

other.

- Using an X-acto, benchtop belt sander, whatever... make both tabs

the same depth.

- Reinstall modified LED cover with the scratched side facing inwards.

- Voila - your LED panel looks like new and doesn't have any unsightly

scuffs or scratches on it.

Thoughts on Adding a HD LED

I am thinking of using 2 colored LED, and replace the power on LED.

From Peter:

Err... that won't work that easy - you will have to rework the

thing a bit more. The Power LED has +5 V as common and GND over resistor, while

the HD-LED signal supplies +5 V activity signal and common GND... except you

have a LED with 4 wires (2 separated LEDs in one unit).

From Jim Shorney:

And I found this out, too. Although the idea is still kicking

around in the back of my mind, behind some other distractions from down

south...

It should certainly be possible to wire in a simple switching circuit with

an NPN transistor on the HD LED to take care of the difference and allow use of

a common-anode bicolor LED, providing the +5 can source a few extra milliamps.

I haven't figured out (yet) if this comes from hard power or is a signal output

from the PS/planar. The other possibility is to use a common-cathode LED and

share the resistor for the power LED, but I'm not sure how well this would

work. LED's are diodes, after all, so the two sources would be isolated from

each other (in theory), but I'm not sure what this would do to the brightness

of the LED's. I may play around with these ideas in the future, but I wanted to

keep the initial mod as simple as possible for those who might be comfortable

with a soldering iron but don't possess sufficient knowledge to handle wiring

up transistors and such.

From Peter:

About the HD-bicolor LED: I still think it is no good idea. The

difference in the color change is... well... hard to see while the green power

part is permanently on. This could work however if you have a "common cathode"

LED and replace the resistor on the PCB with a small 2-transistor 10 mA

constant current circuit. In this case the pin 4 (HD-LED) could be fed directly

to the anode of the red LED part and the +5 V DC (Power) to the green LED part

and the two LEDs share the common GND and the current limiter.

*But* the visibility is still bad. What you need were a "NAND" function that

switches off the green power LED when the red HD LED comes on... that would

make the color either green *or* red but not a diffuse orange when both come

on.

To simplify the circuit you only need to check the HD signal. As long as it

is low the green LED part is on (if there were no power it were dark anyway)

and once the HD signal pin comes "high" the red LED comes on and the green is

switched off... In this case you could even use a "common cathode" bi-color

LED, which are more familiar than "common anode" types IIRC and keep the

existing current limiting resistor on the PCB.

Still too complicated I think. Faster and -to my opinion- better

results are obtained with installing a bright red LED behind the LED

"window"...

From Peter:

> I thought of that as well. But, as you say, it is starting to

get complicated. I'm perfectly capable of whipping something like that up, but

not sure that I want to go to the trouble. I'm trying to stick to something

that just about anyone can whip up.

Currently I have broken down the "logic" to 2 additional resistors

and a PNP-transistor :-) I'll try out if that works on Thursday maybe and let

you know ... I only need to buy a two-color LED. My first "experimental

assembly" will most likely consist out of two standard-LEDs.

> An LED behind the display window seems to be the best overall

solution.

Yep. The current "implementation" looks pretty cool. I

really wonder why the heck IBM did not include a standard HD-LED

in their darn expensive flagship at that time. I think it might be a reason

that they "recycled" an existing panel-unit from a mainframe controller

- and that simply had no HD...

> One of the triangular ones used in tuning indicators and tape player

directional indicators might look cool.

It sure does - but the rectangular types can be easily fixed with

some superglue on one of the existing LED arrays. Whatever - it is possible to

integrate a LED without damaging the panel bezel... and that counts :-)

> I think I would go with green, myself. And I'm still thinking about

replacing the power LED with a blue one...

Matter of personal taste... and I recently found some "blue LEDs"

which are pretty cheap... and no LEDs at all. They are small lamps (bulbs) with

a blue-colored glass. I think VW used them in earlier years for the "hi-beam"

indicator lamp in their cars. They *look* like LEDs - even have the flattened

side - but unlike to LEDs they work in either polarity. :-)

Peter's Two Color HD LED

Peter's minimalistic "Two-Color LED" Solution.

Principle of Operation

You need to unsolder the existing green LED. The +5 V DC contact needs to be

fed to the above circuit. Only the common cathode of the bi-color LED gets

soldered back in the place where the original LED cathode was.

The two LED-parts use the existing 330 Ohms resistor in common. The PNP

transistor gets minus-potential over the 47K resistor and the green LED lights

up. Even when the HD-pin does not feed minus to the resistor (tri-states) the

GND connection is given over the red LED part and the current-limiting

resistor, so that the green LED will light under any circumstance.

Once the HD-pin gets positive (on HD operation) the positive +5 V pulse will

turn Base of the transistor positive and the green LED goes blank - the red LED

is then on and indicates HD activity.

The type of the PNP-transistor is uncritical. Any type will do. I used this

2SA608 while I had it... In case you want to return to original condition you

only need to remove the circuitry and resolder the single green LED. Pretty

easy, eh?

Note: I found out that my original concept works

only with *one* panel card, which sits in a very early Mod. 8595-AH9 (without

shutter). All my machines have the same panel card that Jim described and to

which he published a "revised version" of my PNP-transistor solution. The two

cards only differ through the position of the current-limiting resistor for the

"power LED" - but that makes a bit difference. Sigh.

Shorney's Shortcut

Parts required

- An LED of the size, shape, and color desired

- One .25 Watt, 330 Ohm resistor

- Two short lengths of small-gauge hookup wire

- Some small heat-shrink tubing

- An IBM Model 95

Tools required

- Soldering iron

- Wire strippers/cutters

Instructions

- Trim the leads of the resistor and the anode lead (the long leg)

of the LED short, and solder one lead of the resistor to the anode of the

LED.

- Solder the two lengths of hookup wire to the other resistor lead

and the cathode (short leg) of the LED.

- Cover the soldered connections with the heat-shrink tubing and, well,

"heat shrink" it.

- Pull your 95 apart, and unplug and remove the operator panel display

PCB (you do know how to do this, right?).

- Secure the LED in your desired mounting location (more on this in

a bit) and cut and strip the two free wire ends to length; the anode lead

(the one coming from the resistor) will be soldered to pin 4 of the ribbon

cable connector, and the cathode lead will be soldered to the frontmost

of the two speaker connector pins (ground). Make your connections

on the bottom of the PCB.

- That's it! Install the PCB back in your Model 95, taking care

not to snag your wires as you slide the PCB back in. Enjoy your hard

disk light!

Now, as to mounting location for the LED... Being into vintage ham radio

gear, I subscribe to the "drill no holes" school of mods. Finding a suitable

location for the LED, without altering or detracting from the aesthetics of the

machine, is the hardest part of this adventure.

My first experiment was to tie the new (red) LED to the existing

power LED with a cable tie, so they are side-by-side. This results in an

interesting green-to-red/green effect when disk access occurs that can be

varied by adjusting the positioning of the LED's behind the bezel, but the

result is not easily discernible from a distance or over a very wide viewing

angle. Another thought that occurs it to somehow fix a square or rectangular

(or some other interesting shape) green LED behind the operator panel window,

either dead center above or below the operator display, or in one of the

corners. I may experiment along those lines when I get my hands on some LED's

that are other than round.

...

I finally got around to trying Peter's nifty circuit for a two-color HDD LED

in a model 95. In the process, I discovered that there are at least two

variations of the info panel PCB. Mine differs from Peter's in the location of

the LED resistor, so I had to change the circuit as shown below:

Circuit function is essentially the same, the change was required because my

board has the 330 ohm on the anode of the power LED instead of the cathode, as

shown in Peter's diagram. The green LED does not fully extinguish in this

configuration because the HD output only seems to source about 3.6 volts under

load, but it is dim enough that the red is clearly visible from an angle or a

distance of a couple of feet (meters?).

That having been said, I also tried a rectangular red LED behind the display

panel on another 95. I must say, I like the way it looks. I fixed it with hot

glue to the bottom of the rightmost operator display LED so it appears directly

below the rightmost character of the display. Now I need to decide which way I

like better...

Button Sizes

The button size between "left-hand" and "right-hand" panels is different -

respectively the *length* of the buttons. Ran into this when I swapped a button

from the 8595 onto the 9585.

Early 95s without Shutter over Power Switch

> Early 8595 have no clear springy cover over the power switch. It's

kinda funky looking having a beige "ring" around the white switch.

Power switch protective shutters became standard in early 1992. 8595 before

then lacked them.

Tony Ingenoso replies:

These are the earliest models - undoubtedly a T1. That "feature"

was rectified fairly quickly when the complaints rolled in from the field.

People who had 'em on the floor were turning them off by mistake thinking they

were reaching for the FDD eject button. This is one of the few truly lame

things about the 95 — because the test labs were complaining about the

same thing fairly early on.

Free PS/2 Model 95 Power Switch Upgrade

(source) (H095521)

As a result of customer requests, the PS/2 Model 95 information/power bezel

has been redesigned. The new design will minimize or eliminate accidental

depression of the power switch when diskettes are inserted or ejected from

drive A:. New Model 95s will ship with this bezel.

The new switch has a clear plastic "trap door" over the power switch. To

enable the switch to be depressed, the "trap door" must be raised by placing a

finger under it and sliding it up. The FRU number of the bezel (33F8423)

remains the same, but will now include the redesigned bezel.

Effective August 20, 1991, and continuing until January 1, 1992, the

redesigned power/information panel is available free of charge in the U.S. to

customers who purchased 8595 systems with the early style panel. Customers may

call toll-free: [number redacted] to have the panel(s) direct-shipped to them

at no charge.

The new power panel is easily installed by the user. Pictorial

removal/replacement instructions are included with the replacement panel along

with a shorter pushbutton and a pushbutton removal tool.

Op Panel Bezels and PCBs

8595 Op Panel

Early 8595 Op Panel Bezel, Front 33F5408

This is one of the earliest Op Panel bezels, note the lack of a shutter over

the Power Switch button, Power Good LED, and the raised edge around the button.

Note that the bezel hooks are on the LEFT and the bezel latches are on the

RIGHT. (Thanks to Jelte for pix)

Early 8595 Op Panel Bezel, Rear 33F5408

Note the simplicity of this moulded part. See the EMI shielding? That copper

colored coating is replaced on later bezels by the silvery Enshield (which was

probably cheaper as well...). Note the small locating posts at the upper

corners? They fit into holes in the DASD retainer.

Later 8595/9595 Op Panel Bezel, Front

This is not the earliest, as it has the shutter over the Power Switch

Button. Note that the bezel hooks are on the LEFT and the bezel latches are on

the RIGHT. It has a Power Good LED and an Information Panel window.

Later 8595/9595 Op Panel Bezel, Rear

Note the small locating posts at the upper corners? Note the modular

assembly, with the white button frame being placed onto the bezel (grey). Peter

mentioned that the op panel PCB originally came off an older existing device.

Also note the LED window is covered with a darkly shaded piece of plastic. If

the plastic window got a little scuffed up, you can push the flexible sheet

out, and the tabs will pop out of the frame with no damage. To re-install the

window, put one tab in the slot, and bow the sheet a little until the tab

re-enters the opposite slot.

Op Panel Shutter Spring

The spring powering the shutter rests on a little hook molded into the

shutter. If the shutter haltingly raises, check to see that the end of the

spring is in the hook, not dragging between the front of the hook and the white

module. Note the white hook just above and right of the end of the spring. To

remove any spring tension from the shutter, place the end of the spring into

the hook.

Correct Spring Position (Lorenzo)

The photo above shows the shutter spring in the correct position.

Incorrect Spring Position (Lorenzo)

Note the shutter spring is in front of the little "wings" used to guide the

shutter up and down. The shutter spring rubs against the subframe, and the

shutter no longer moves smoothly. In addition, the shutter is pulled back into

the subframe causing resistance as well...

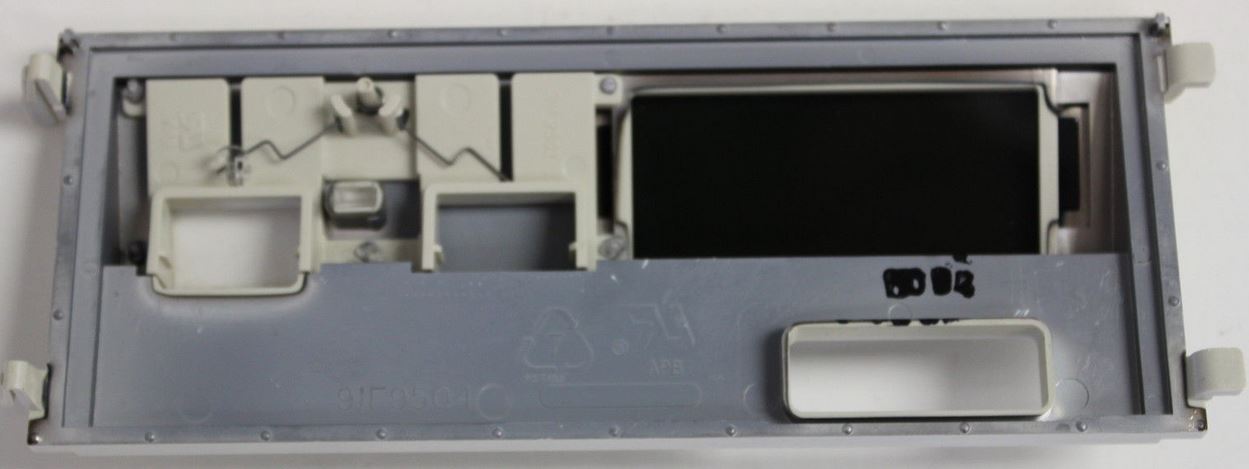

8595 / 9595 Op Panel PCB, Top (Jelte)

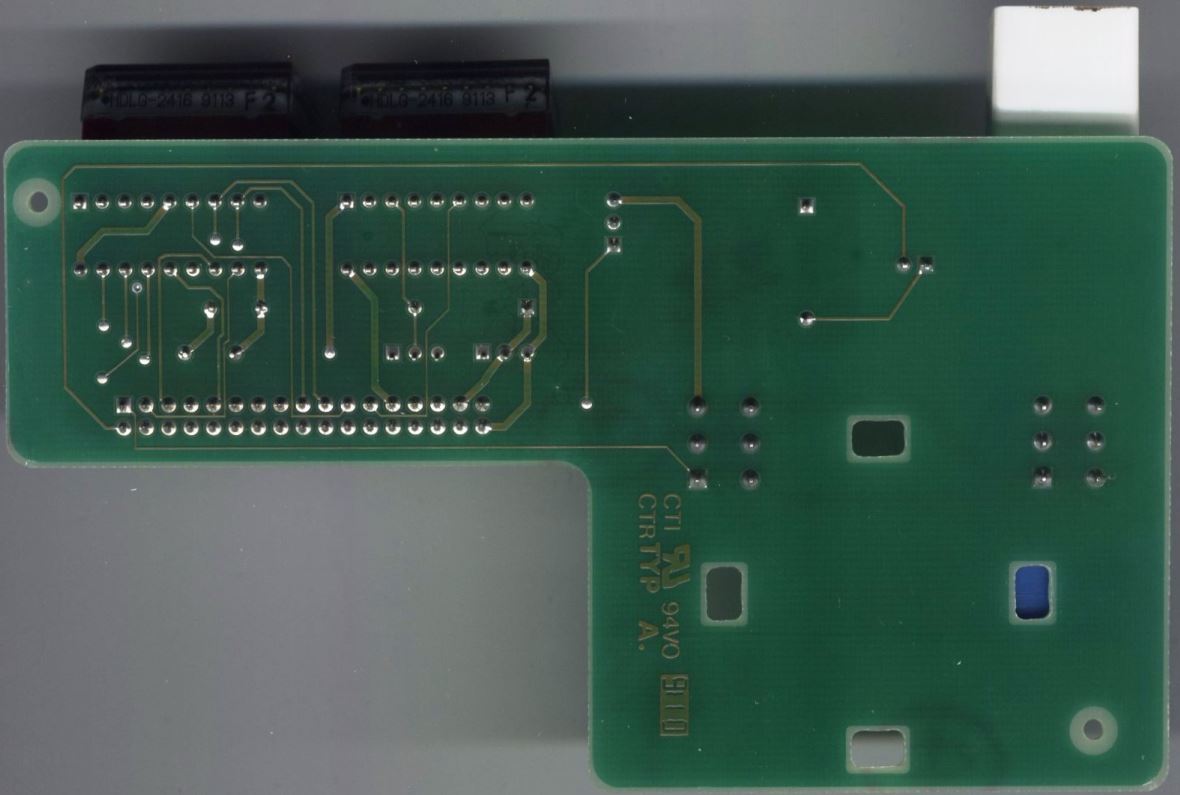

8595 / 9595 Op Panel PCB, Bottom (Jelte)

8595 Frame (Jelte)

See the rectangular holes on the left for the Op Panel Bezel hooks, while

there are similar "T" shaped holes to the right. Note there is only ONE set of

small holes for the Op Panel bezel at the top corners. Note the small hole for

the alignment pin in the upper left corner is horizontally elongated, while the

upper right pin hole next to the latch hole is round. This makes sense, as the

hooks on the left are inserted first, and the left pin makes an arc as it

enters the hole. The rightmost pin is near perpendicular as it enters the hole

near the latch.

9595 Single Serial Frame (Lorenzo)

Same as the -AKD, I would surmise the bezel mounting holes changed with the

9585 (K/N?) and 9595A (Dual Serial/Parallel) models.

Note that the hook /latch holes are slightly inward from center. Maybe

because it was better to not have the drive retainer hooks in-line with the

bezel fasteners? Dunno.

3511 Op Panel

3511 Op Panel Bezel, Front 64F0131

The 3511 uses a bezel derived from the "later" 8595 assembly - but with the

LED display window covered.

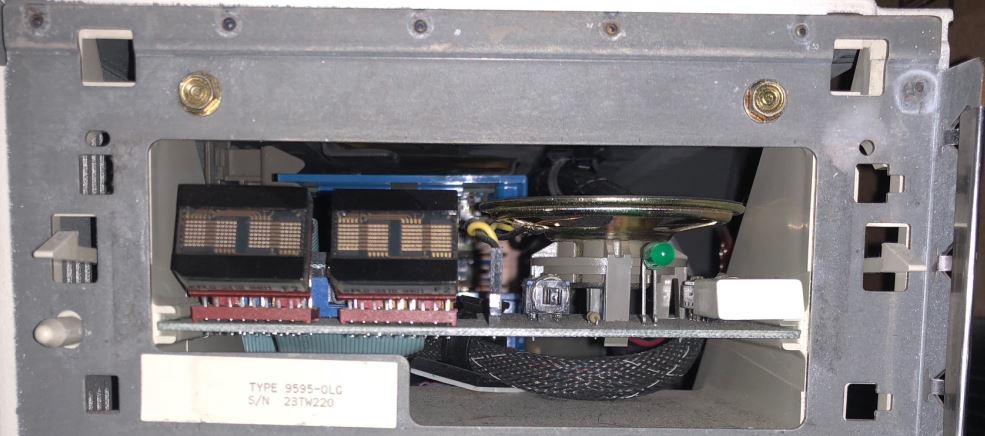

3511 Op Panel PCB, Top 64F0143 (Mad Max)

3511 Op Panel PCB, Bottom 64F0143 (Mad Max)

This is the same Op Panel PCB as in the original 8595. However, only the

power switch, Power Good LED & resistor, and a smaller (10-pin) header are

populated. There is a wire between pins 5 and 14 of the LED unit U1 -

redirecting the +5 V rail to pin 9 of the J1 header (normally +5 V is on pins

25, 27, and 31 - unpopulated here). The corresponding 10-wire cable can be seen

HERE.

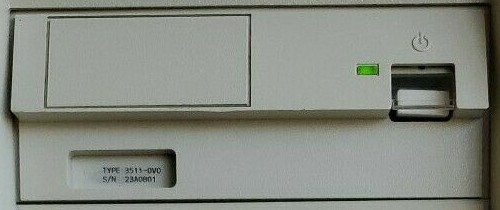

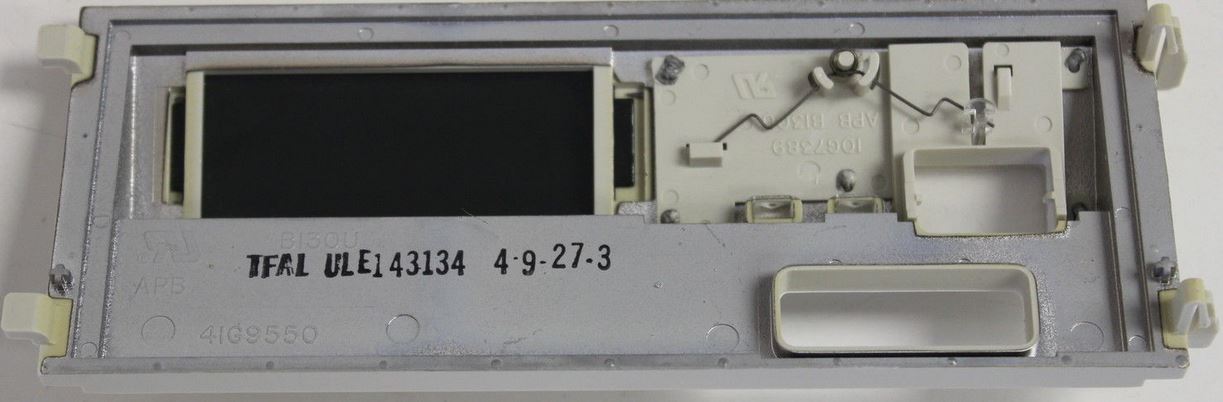

9585 Op Panel Bezel, Front 41G9550

9585 Op Panel

This bezel has a shuttered Power Switch Button, a Power Good LED, a HDD

Activity LED, but the Information Panel window has a opaque plastic insert. Note

the bezel latches are on the LEFT and the bezel hooks are on the RIGHT.

9585 Op Panel Bezel, Rear 41G9550

Note the small locating posts have been moved from the upper corners to just

above the lower hook / latch? Note that the Information Panel window insert

(57F2085) has the same tab arrangement as those for LED displays. The power

button frame has lost the well for a second push button, and a second LED light

pipe has been added.

9585 Op Panel PCB, Top 61F3736 (David Beem)

9585 Op Panel PCB, Bottom 61F3736 (David Beem)

9595A Op Panel Bezel, Front 41G9550

9595A Op Panel

This bezel has a shuttered Power Switch Button, a Power Good LED, a HDD

Activity LED, but the Information Panel window has a darkly shaded piece of

plastic. Note the bezel latches are on the LEFT and the bezel hooks are on the

RIGHT. The 9585 and 9595A use the same bezel.

9595A Op Panel Bezel, Rear 41G9550

Note that the Information Panel window insert has the same tab arrangement as

those for LED displays. The power button frame has lost the well for a second

push button, and a second LED light pipe has been added.

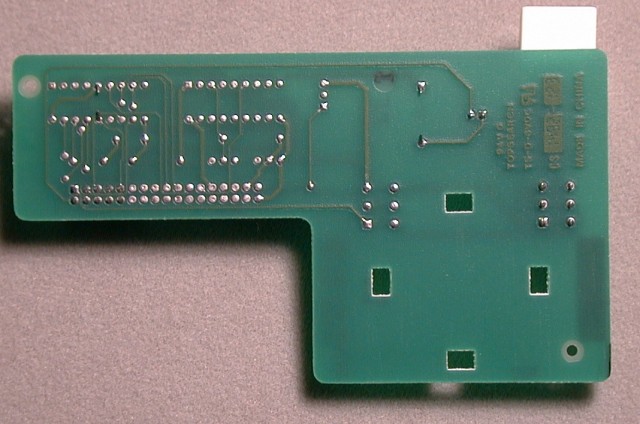

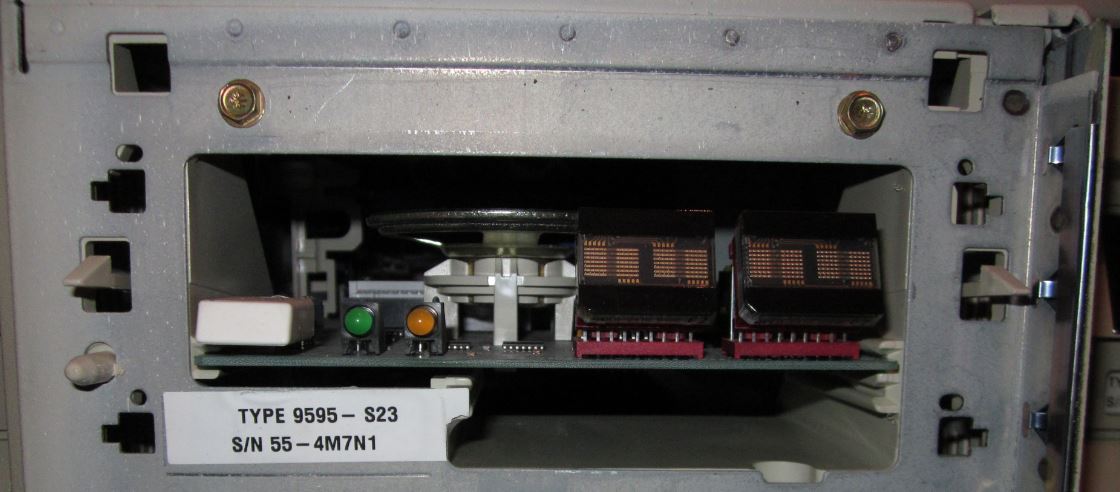

9595A Op Panel PCB, Top 92F0259 (Jelte)

9595A Op Panel PCB, Bottom 92F0259 (Jelte)

9585 and 9595A Frame (Jelte)

See that the hook -AND- latch >BOTH< use a "T" hole? Note there are

TWO sets of small holes for the Op Panel bezel pins, at the top corners -AND-

above the bottom hook / latch holes. I suppose you could use one LED bezels on

8595 >AND< 95A frames... Note the elongated hole for the top posts is on

the left, and the elongated hole for the bottom posts is on the right.

What is the second card guide doing there? See, the Op Panel board is in the

upper card guide, and the narrower bottom guides are empty. Note the notch in

the frame in the lower right (below right 4 character LED), and the

semi-circular relief in the plastic DASD Support Structure... Almost resembles

a relief for a thumb wheel... Multimedia Option?

Power Switch Test / Jump Start

Pull Op Panel out front of system. Leave PSU plugged in. Unplug the molex

connector(s) from the PSU if you don't want your hard drives to spin up/down

during the testing.

For the single LED (95 XP) Op panel: Short pin 1 (or 4) to pin 2 (or 5)

and the PSU should start.

For the dual LED (95A) Op panel: Short pin 1 to pin 2 and the PSU should

start.

Operator Panel Registers

See Hex 0108-010F for info about Op

Panel registers.

Panel Programs

PS2INF.ZIP Small program to access the LED Panel (DOS, OS/2 driver).

DLITEDOS DOS device driver for HD display on Model 95 LED Panel

PANEL OS/2 device driver for character display on Model 95 LED Panel

BASIC Way

From Peter (edited):

Use this little Basic program to write anything into the panel.

Substitute A$ with your text:

A$ = "133 MHz "

FOR q = 1 TO 8

OUT (&H107 + q), ASC(MID$(A$, (9 - q), 1))

NEXT q

You can as well use DEBUG's "OUT {portnumber} {value}" command to pipe into

the display. Write a text that includes 8 lines of out commands to the ports

108h - 10Fh with the hex character values for {value} and use

DEBUG<mytext.txt to bring it into the panel.

(30 is "0", 39 is "9", 41 = "A" 5A = "Z")

Linuxinfo

If you have a Model 95 (8595, 9595), you can get the source of linuxinfo,

that is linuxinfo.c. This

program shows you the current CPU-load, date, time and the kernel-version on

the 95s' LED display. The information is continuously scrolled from right to

left. This allows system-load-control, even if you are not logged-in and no

monitor is connected to the system (like in central computing rooms). As the

two very right LED letters are kept blank, it works great together with the IBM

SCSI subsystem driver with the command line-parameter ibmmcascsi=display.

LED Panel Odd Behavior

From Alfred Arnold:

Last week, I was able to get my hands on a 8595-AKF (Type 1

complex, 486DX33, no cache module :-( ). The price was on a per-kilogram basis,

so I was quite happy. However, when installing Linux and my own tool to display

some system statistics on the LED display, I noticed a strange behavior I

hadn't seen before on a 9595 with a P60 complex: Even under Linux, there seems

to be some type of 'demon' that regularly clears the right half of the display.

I also saw this under plain DOS, but I thought first this were a 'feature' of

the BIOS. However, since this also happens under Linux, either something on the

planar is slightly broken, or there are some implicit links between the LED

display and other parts of the planar's hardware I'm not aware of. I don't hope

it's the first case ;-)

From Peter:

> Even under Linux, there seems to be some type of 'demon' that

regularly clears the right half of the display.

On the -AKF this is surely a bug rather than a feature. The

LED-panel is directly controlled from the sysboard I/O ports and it looks like

a buggy display element (2 x 4 digits). Check if it is properly seated or has

bad solder spots. Also check if the panel cable is in good order and properly

seated.

Alfred Arnold retorts:

Hi Peter, took out my Tek yesterday evening and probed around a

little bit. It doesn't seem to be a problem in the display element itself,

since swapping them doesn't help...the interesting thing is that during POST,

the write signal for the bottom display half is overlayed with a 250 Hz signal,

which however has not full level. So either the driver chip on the planar has

gone bad or there is a short to another signal. Seems I have to disassemble the

whole beast :-/

And finally, the moment of discovery:

By the way, I was able to fix the display yesterday evening. There

was a bad contact in the display module's socket, but one that can make you

tear out your hair...there was no contact to the Vcc pin of the display, but it

still somehow worked because it supplied itself with power via the other signal

pins (probably via the usual CMOS protective diodes). You could put a scope on

the /CLR pin of the display module and see how the voltage started to ripple

when one digit was turned on. Turn on a second digit, and the voltage broke

down finally and the display resets...

8 "Lights" on Op Panel

I have been having some trouble with getting a Model 95 to see the optical

SCSI drive being added. I went in and unplugged the SCSI cable, and power cable

to reset everything and start over. Now I have 8 positions across the op panel

with a pattern of small dots (LEDs) and the machine goes no farther in the boot

process. What do the 8 position, all LEDs on suggest.

It suggests you pulled one end of the cable going to the LED display loose

at one end or the other or that you somehow damaged the cable to it. Check for

this small flat cable and make sure its OK.

Jack, I had high hopes that it would be that simple. I checked and

re-plugged both cables and did not change my symptom. Any other ideas. I have

an HMM dated Sept 1993. Where did you find the symptom info.? Did you get it

from the HM manual?

From Jack Gulley:

The HMM will not give you details on what's wrong. The symptoms

indicate one of the lines to the operator panel has a hot or shorted bit. If it

is the same bit in each of the 8 display position, it indicates a common line

or driver problem. If the bit come on as soon a power comes on and nothing else

ever displays, then it very likely the operator panel is blown. Problem

isolation is simple - replace the cable, then the electronics at each end of

the cable, after first making sure everything was plugged in and the cable not

damaged.

|