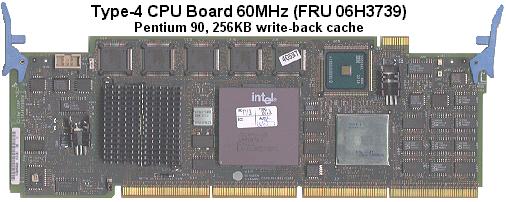

(Photo from Peter Wendt/Dennis Smith's MCA card picture collection)

Content Copyright 2003, Jim Shorney, all rights reserved. Edited by Major Tom.

Why the "Y"?

The Pentium 90 IBM "Y" processor complex for PS/2 Model 90/95 computers

is the most highly sought after PS/2 upgrade because of it's speed and

upgradability. However, some people have experienced unexplained

failures of an otherwise very reliable processor complex after upgrading.

Why? I believe that some of the failures can be attributed to the

power system for the CPU.

The Pentium 90 (actually, Pentium 75 non-MMX and above) CPU is a 3.3

volt CPU. The earlier P60 and P66 CPUs used a single 5 volt power

supply. To provide 3.3 volts for the CPU and the I/O section of the

80497 cache controller, IBM added a second voltage regulator to the circuit

board. While this regulator is adequate for the original 90 MHz CPU,

it is my belief that is needs some rework to handle faster CPUs.

One important factor that many upgraders fail to take into consideration

is the power requirement of the new CPU. This is OK for the typical

socket 5 or 7 clone motherboard, since (for the most part) they are designed

to handle a variety of CPU chips. The Y complex, however, was designed

for only the P90 CPU, with no upgrade envisioned.

Below is a table of the relevant power specifications for several CPU chips

that have been used with the Y. Current specifications are worst-case

values, and are taken from relevant Intel

documentation; Regulator power dissipation was calculated assuming

1.7 volts drop across the CPU regulator.

| CPU Speed |

Supply Current (Amps) |

Regulator Dissipation (Watts) |

| 90 |

2.95 |

5.015 |

| 166 |

4.25 |

7.225 |

| 200 |

4.60 |

7.82 |

| 180 Overdrive |

4.33 |

7.361 |

| 200 Overdrive |

5.00 |

8.50 |

Here we can see that even one of the simplest upgrades to implement,

the 180 Overdrive, draws over 1 Amp more than the stock CPU, and increases

regulator dissipation by over 2 watts! An interposer that provides

a separate power source is one solution that is under investigation by

others. I think my solution is equally viable, and has the advantage

of being cheaper to implement.

The Regulator

The CPU voltage regulator is a three-terminal, low dropout voltage device,

the LT1084CT.

It has a typical current limit of 5.5 Amps, so it should be capable of

handling the upgrade. In fact, this same device is commonly used

on Socket 5 and 7 clone motherboards rated for 200/233 MHz CPUs.

So where's the problem?

The Heatsink

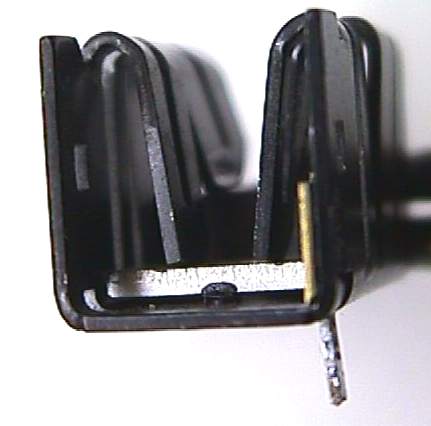

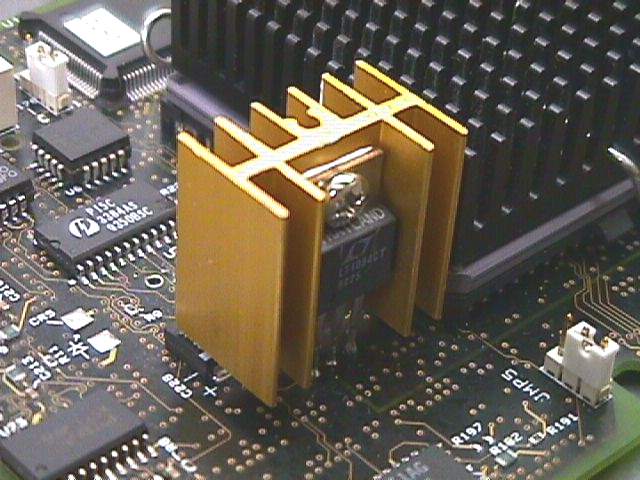

IBM used two different heatsinks for the CPU regulator. One appears

to be a Thermalloy PF430, similar to the Thermalloy PF432G,

the other is similar to an Aavid/Thermalloy 576802.

They are both very similar in size, and are rated for a thermal resistance

of around 25 °C/Watt. I won't go into the thermal calculations

here, but this unit seems entirely too small to dump over 7 watts of heat

into the air. Also, the PF430 has a design flaw which would seem

to make it inadequate for all but the smallest jobs. Look at this

picture (all photos are clickable):

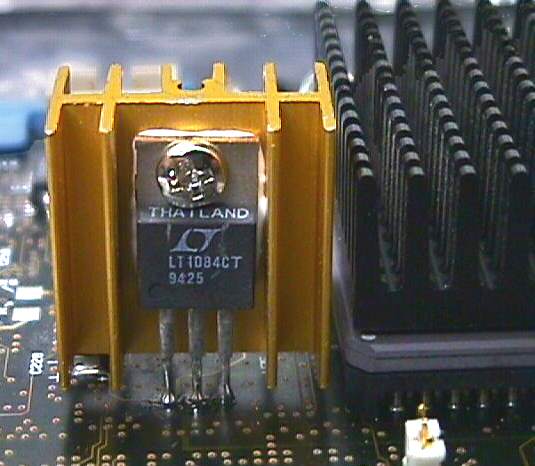

The area of concern is circled in red. The tab of the regulator

IC rests against the horizontal flat. The raised area below creates

an air gap between the regulator tab and the heatsink, which prevents efficient

heat transfer to the heatsink. The next pictures show the air gap:

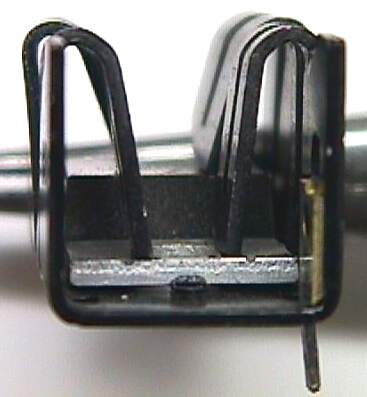

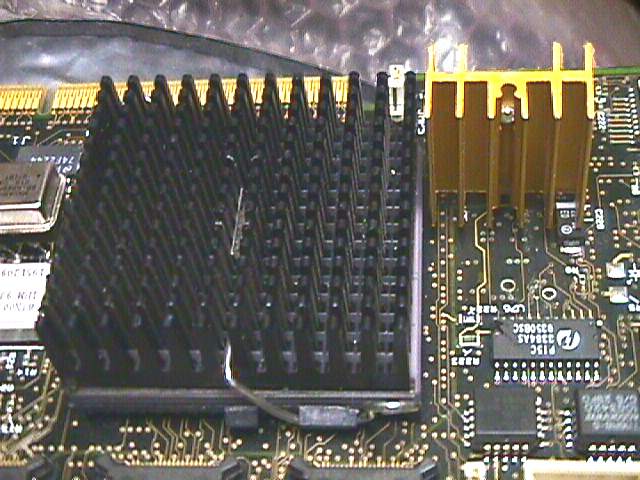

The Aavid design does not suffer from this flaw, as can be seen in this

photo:

These sinks were removed from two different P90 complexes. Noticeably

absent from both configurations is thermal heatsink compound between the

regulator and the sink; further evidence that this was not meant to handle

a lot of power.

Making it Better

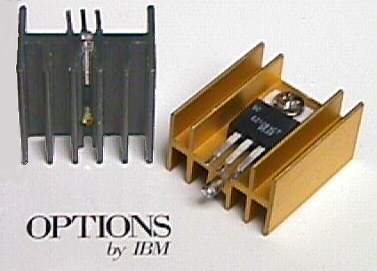

One obvious solution to the problem is to install a better heatsink

on the CPU regulator. I dug through a stack of dead clone motherboards,

and found these heatsinks:

They are both from socket 7 75-200 MHz boards that use the LT1084CT

regulator, so they should be adequate. I chose the gold one because

it has two more fins, and, well, because it's prettier!

Important:

The processor complex is a static-sensitive device! When doing any

work on it, be sure to use standard precautions. Use a grounded soldering

iron, and make sure that you are discharged before touching anything on

the board. It is a good idea to get one of those large anti-stat

bags that clone motherboards come in, and lay the complex on it while working

or any time the board is out of the computer. Your local clone mill

should have lots of these bags laying around. You don't need a big-money

anti static workstation to do this, just a good dose of common sense.

The stock heatsink has one solder tab in the upper left corner that

secures it to the board. Heat this up with a soldering iron

and pull the sink up away from the board. It should slip right off

the regulator once it is loose from the board (another sign of less than

ideal thermal contact...). Pull the mounting pin out of the bottom

of the new heatsink with pliers. Carefully stand the regulator straight

up from the board by straightening out the legs, and bolt the new heatsink

to the regulator tab. Be sure to use a thin coating of heatsink compound

between the regulator and the sink. Make sure the sink does not come

into physical contact with any other components. There should be

enough clearance for everything unless you find a truly monster heatsink,

and it should be mechanically stable enough unless you are planning to

ship the machine somewhere or launch it on the space shuttle. In

this set of photos, the stock P90 CPU is still installed.

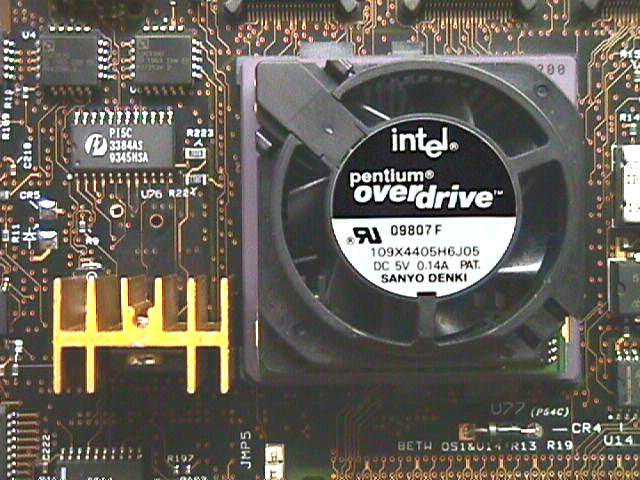

The 'turbo-sink' Y complex with Intel Pentium Overdrive, operating at

60/180 MHz, fitted:

Tim Taylor would be proud!

On this complex, I also replaced the Thermalloy heatsink on the LT1085

regulator with the Aavid unit that was removed from the CPU regulator.

So we're done, right? Well, not quite...

We need more power, Scotty!

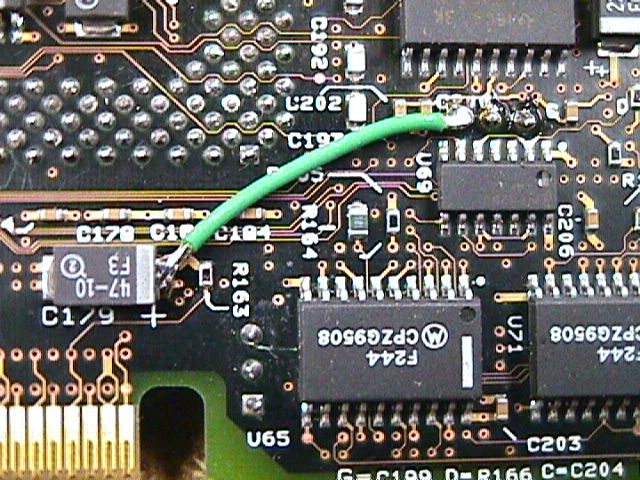

What we have now is a CPU drawing more than 7 amps through one connection

point: a plated-through PC board hole that is tied to an inner layer of

the circuit board (the +5 Volt power plane). Call me paranoid, but

I don't like that. I chose to add two jumper wires from nearby +5v

points to the regulator input to spread the current flow out, as shown

in the next set of photos. One wire connects to the anode of diode

CR4 on the top side of the complex, the other to the positive terminal

of capacitor C179 on the bottom. I also made the

fan connection

for the Overdrive CPU to C179 (not shown in this photo).

A word about the fan connection: you might think that there is enough

airflow in the 95 case that you don't need the CPU fan on the Pentium Overdrive.

Whether this is true or not, I don't know. But the fan is needed

for another reason besides cooling: the POD has a tach sensor circuit built

into it that reads a tach signal from the fan (the third electrical contact

on the fan). No fan spin = no tach signal, and the CPU downclocks

automatically to protect itself. It still runs reasonably fast, and

can fool you with some benchmarks, but it's not running as fast as it should.

Was all this worth it? I made a simple temperature probe for my

digital multimeter and did some tests. The stock regulator/heatsink

combo hit 55 °C at 100% CPU load, while the new heatsink never got

above 45 °C. I can't vouch for the accuracy of this crude test,

but the results are reasonably close to what I would have expected.

All the images on this page were prepared on the machine that is running

this modified complex.

Why all this fuss about cooling? Click

HERE

for one explanation. Since PC Power and Cooling keeps changing the

location of that link, here's the pertinent text:

Operating Temperature vs System Reliability

At elevated temperatures a silicon device can fail catastrophically,

but even if it doesn't, its electrical characteristics frequently undergo

intermittent or permanent changes.

Manufacturers of processors and other computer components specify a

maximum operating temperature for their products. Most devices are not

certified to function properly beyond 50°C-80°C (122°F-176°F).

However, in a loaded PC with standard cooling, operating temperatures can

easily exceed the limits. The result can be memory errors, hard disk read-write

errors, faulty video, and other problems not commonly recognized as heat

related.

The life of an electronic device is directly related to its operating

temperature. Each 10°C (18°F) temperature rise reduces component

life by 50%*. Conversely, each 10°C (18°F) temperature reduction

increases component life by 100%. Therefore, it is recommended that computer

components be kept as cool as possible (within an acceptable noise level)

for maximum reliability, longevity, and return on investment.

* Based on the Arrhenius equation, which says that time to failure is

a function of e-Ea/kT where Ea = activation energy of the failure

mechanism being accelerated, k = Boltzmann's constant, and T = absolute

temperature.

Getting to 200 MHz

If you dare, the complex can be overclocked to 66 MHz on the bus, to

achieve 200 MHz (or even 233 with an MMX interposer) with Intel CPUs.

Here's one way to socket the oscillator module:

I took an 8-pin DIP socket with machined contact pins and bent pins

1-2, 3-4, 5-6, and 7-8 together in a 'V' shape. It's a perfect fit

to the foil pads on the circuit board! Half-can oscillators that

fit this socket can be purchased from Digi-Key.

9/4/2004 - Some comments on 233 MHz: it's not worth it, in my

opinion. Based on empirical results posted to CSIPH newsgroup,

233 MHz is problematical and more often doesn't work well or at all.

That extra 33 MHz of speed is insignificant, and more trouble than it is

worth to achieve. Here are some comments from Peter Wendt on the

subject:

I don't know the Kingston Upgrade too good, have seen it a couple

of times, but don't have one for testing. So most of my reply is purely

theoretical and based on assumption and experiences I made with different

upgrades.

1. In a different thread in this group I'd shared my impression that

a bus /core ratio above 3 is a bit tricky to handle for the complex card.

Particularly for a 1:3.5 ratio, which *rarely* synchronizes with the 40

MHz DMA and MCA bus controller clock.

In addition the "time window" for synchronization is rather short anyway

and gets even shorter if the bus clock and internal CPU speed differ more

and more. I only have empirical data gained from weeks of experimenting

with the Madex 486007 adapter and a known-good Pentium 233-MMX CPU in an

otherwise stable and well-tested system. The number of crashes and bluescreens

was significantly higher (about 10 times) than with the Pentium Overdrive 200

MMX or with the upgrade adapter running in 3x mode (200 MHz internally).

2. You should take in account that the power drawn by the processor

*may* exceed the onboard 3.3V regulator capabilities - or that of its heatsink.

Less likely however, but we should keep an eye on it. The upgrade is usually

fed from +5 / +12V from the main power supply directly. Usually this is

only the secondary supply for the CPU core - but the rest of the CPU still

runs from off the standard 3.3V regulator. I don't know how the Kingston

gets the core power. If it has no direct connection to the power supply

there might be the reason for frequent crashes: According to the worst

case specs from Intel the 233MMX draws 6.5 Amps on the 2.9V core and 0.75

A on the 3.3V supply. Altogether it sums up to over 21 Watts electric power

- which is far outside the specs for the LT1084 regulator.

3. Cooling is important. Most likely the Kingston kit has a built-on

fan. Does it work ? Is it fed from the main power supply as well ? Or is

the Kingston originally intended for Socket-7 boards ("Overdrive Ready")

only ? The P90 platform is a Socket-5. Not Overdrive Ready and therefore

lacks the two +5V DC fan supply pins. If the CPU fan does not work the

233MMX reacts rather allergic, since it overheats in a few minutes already

- and it has no thermal self-protection, other than the Intel Pentium Overdrive

200 for instance.

4. MMX technology and the 82497 cache controller usually work together

- other than in P60/66 systems with the 82496. I myself run a machine with

the Pentium Overdrive 200 and I did ran one with the Madex and a P-233MMX

- but clocked down to safe 200MHz for an extended time with no problems.

5. The change from 60 to 66MHz does not matter (much) to cache controller

and cache RAMs, even if they are spec'd as -60 parts. The 10% overclocking

(if any) usually causes no problem. None of my machines ever complaint

nor crashed more often than usual. At least not significantly. If you run

Windows you are used to frequent crashes anyway.

Well - I guess that I can't tell you more at that point. As said: I

don't have the Kingston and have no experiences with it.

9/27/2006 - More on the 233 MHz adventure: user reports indicate

that BIOS level 08 seems to have the best chance of working with a 233

MHz CPU/interposer combination. BIOS levels higher than 08 are likely to

hang with a 0129XXXX error.

Check Sandy's

Pentium Interposers and Upgrades

page for more info about interposers.

Thanks to Clinton M. (classic PS/2 driver) for digging this info out of the

dark recesses of the internet.

To date, no AMD CPU attempts have been

successful.

|